Last updated: January 2026

2030 isn’t just a deadline – it’s when companies without compliant reuse systems lose access to the EU market entirely. No fines, no grace period. But the real inflection point comes much sooner, on August 12, 2026.

If your company operates in or ships to the European Union, the Packaging and Packaging Waste Regulation (PPWR) will fundamentally change how you approach packaging. This isn’t incremental reform. It’s a complete restructuring of packaging requirements across the EU and companies that wait until 2029 to prepare will find themselves locked out of the market.

The Regulation That Changes Everything

The official EU PPWR regulation entered into force on February 11, 2025. The general application date is August 12, 2026. After that date, non-compliant companies cannot participate in the EU marketplace.

This regulation applies to every company operating within the EU and every company shipping product to the EU.

The PPWR timeline includes critical milestones:

- 2026: Elimination of banned substances (including PFAS), reuse systems operational

- 2028: Standardized labeling requirements, HORECA reusable take-away options

- 2030: 40% transport packaging reuse mandate (B2B between companies/states), single-use packaging bans enforced

- 2040: 70% transport packaging reuse mandate

For companies unfamiliar with the regulation’s scope and complexity, our PPWR FAQ provides detailed answers to the most common questions.

Why PPWR Exists - The Waste Crisis That Forced Action

The EU didn’t create this forward-thinking packaging regulation in history overnight. It took decades of data collection and education. The data told a story that could no longer be ignored.

In 2022, the average EU citizen generated 186.5 kilograms (411 pounds) of packaging waste. From 2011 to 2022, total packaging waste across the EU increased by 14.3 million tons, a 20.6% increase in just over a decade, according to Eurostat packaging waste statistics.

Ready to understand your compliance timeline?

The EU looked at this trajectory and determined it was unsustainable. The result: PPWR, a regulation designed to reverse decades of waste accumulation through mandatory action.

The regulation’s objectives are clear:

- Prevent and reduce packaging waste through reusable and refillable systems

- Make all packaging on the EU market recyclable in an economically viable way by 2030

- Safely increase the use of recycled plastic and decrease virgin materials

- Achieve climate neutrality by 2050

This isn’t just an environmental policy. It’s an economic reality. Reusing and recycling packaging reduces material costs, labor expenses, transportation costs, and operating expenses. For companies willing to adapt, PPWR represents a competitive advantage, not just a compliance burden.

What PPWR Requires - The Critical Requirements

The regulation sets specific, measurable targets that companies must meet:

Reuse requirements for transport packaging:

- By 2030: 40% of transport packaging must be reusable for B2B transactions between different companies or member states

- By 2030: 100% of transport packaging must be reusable for B2B transactions within the same company or within the same member state

- By 2040: 70% of transport packaging must be reusable for B2B transactions between different companies or member states

Single-use packaging bans (effective January 2030):

- Plastic wrap for grouped packaging without handling advantage

- Plastic packaging (nets, bags, trays) for unprocessed fruits and vegetables under 1.5kg

- Single-use condiment and sauce plastic packaging in HORECA for on-site consumption

Additional requirements:

- Minimize headspace and weight – no unnecessary packaging or void space

- Meet specific recycled content percentage targets for 2030 and 2040

- Eliminate PFAS (“forever chemicals”) from packaging by August 2026

- Implement EU-wide harmonized labeling requirements

But the regulation includes exemptions, linked enterprise rules, and labeling requirements that vary significantly by company type and structure. Understanding which rules apply to your specific situation requires careful analysis. We break down all 15+ compliance requirements in our guide.

The Hidden Complexity Most Companies Miss

One of the most misunderstood aspects of PPWR is the concept of “linked enterprises.”

A linked enterprise is defined as a company holding 50% or more of the capital or voting rights of another company, or companies controlled by the same entity. This classification, established in EU legislation dating back to 2005, has significant implications for PPWR compliance.

If your organization qualifies as a linked enterprise, you face different requirements:

- Consolidated reporting and financial accountability across all entities

- Aligned packaging formats and sustainability strategies across different countries

- Aggregated data that affects SME status and eligibility for lighter compliance rules

- Consistent labeling, documentation, and recyclability standards across all subsidiaries

Many multinational companies don’t realize they’re classified as linked enterprises under PPWR definitions. This changes their reuse targets, reporting obligations, and compliance timelines dramatically.

Does your organization qualify as a linked enterprise?

What are the failures companies need to avoid?

The problem isn’t awareness. It’s execution.

Companies focus on what happens when packaging is full. They optimize product protection, minimize damage during transit, and ensure efficient loading. But when packaging is empty, many companies don’t have a plan. Under PPWR, that approach fails immediately.

The infrastructure gap is real:

- Most companies lack a packaging database at the SKU level – data essential for measuring compliance

- Reverse logistics infrastructure for recycling certain types of material across Europe remains fragmented

- North American companies shipping to the EU often haven’t started their assessment

- Digital tracking systems for reusable packaging aren’t standardized

Companies that haven’t started building their packaging database face a tight timeline to meet the August 2026 deadline. The first step of understanding legal obligations and cataloging every packaging SKU takes months, not weeks. It requires cross-functional coordination across quality, manufacturing, supply chain, and compliance teams.

The companies that solve this infrastructure challenge now will lead their markets for the next decade. Those that wait will scramble to find solutions in an increasingly capacity-constrained market.

The Three-Step Path to Compliance

ORBIS Corporation has developed a proven three-step implementation process created for companies in Europe and those shipping to Europe to achieve PPWR compliance. This framework works regardless of company size, industry, or current packaging portfolio.

Step 1: Legal Obligations & Packaging Database

The first step is to understand exactly what the regulation requires for your specific organization.

This means finding PPWR compliance experts internally or externally who understand how the regulation applies to your company’s structure, supply chain, and market presence. It means determining your linked enterprise status. And it means building a comprehensive packaging database at the SKU level.

Your packaging database must include:

- All primary, secondary and accessory packaging components

- Hazardous goods and banned substances identification

- Headspace and void space measurements

- Supply chain characteristics (domestic EU, cross-border EU, non-EU to EU)

- Recyclable content percentages

- Recyclability capability assessments

- Labeling requirement compliance

Our guide includes the complete checklist of what must be in your packaging database; the 12 data points per SKU that compliance auditors will require.

Step 2: Packaging Solutions Development

Once you understand your legal obligations and have cataloged your existing packaging, you can assess what needs to change.

This step requires taking a long-term view. You’re not solving 2026 compliance alone, you are building standardized and repeatable systems that will carry your company through 2030, 2040, and beyond.

The process includes:

- Applying a compliance lens to existing packaging (40-50% of SKUs may already be compliant or exempt)

- Conducting an internal “voice of customer” across quality, manufacturing, supply chain, transportation, and customer-facing teams

- Developing a scoring system that balances cost, ease of compliance, supply chain disruption, and implementation timeline

- Selecting the best packaging solutions for each non-compliant SKU

Not every application lends itself to reuse. For some SKUs, recyclable, expendable packaging may be the optimal solution. The key is making informed decisions based on comprehensive data.

We’ve created a scoring matrix that helps you prioritize which packaging to tackle first. Get the full framework in our guide.

Step 3: Execution & Implementation

The final step is where strategy becomes reality.

This phase includes packaging testing in your actual supply chain, packaging optimization (adding recycled content, changing materials), and determining your packaging management structure. Questions including if you will manage packaging in-house or work with a third-party provider and if you will buy outright, rent or lease-to-own?

The critical element most companies overlook: Standard Operating Procedures (SOPs).

To fully comply with this broad and sweeping regulation, you will be changing people’s daily work. You will need to document:

- How empty packaging gets collected

- Who cleans it and where

- How it gets redistributed back into your supply chain

- Who tracks it and with what systems

- What happens when packaging is damaged or lost

Stakeholder alignment across all affected departments is essential. So is building or contracting the reverse logistics infrastructure to handle collection, cleaning, and redistribution of empty packaging at scale.

The implementation phase includes a decision tree for different industry packaging applications. Our guide breaks down each one with timeline estimates and resource requirements.

Get the complete three-step framework

How ORBIS Supports PPWR Compliance

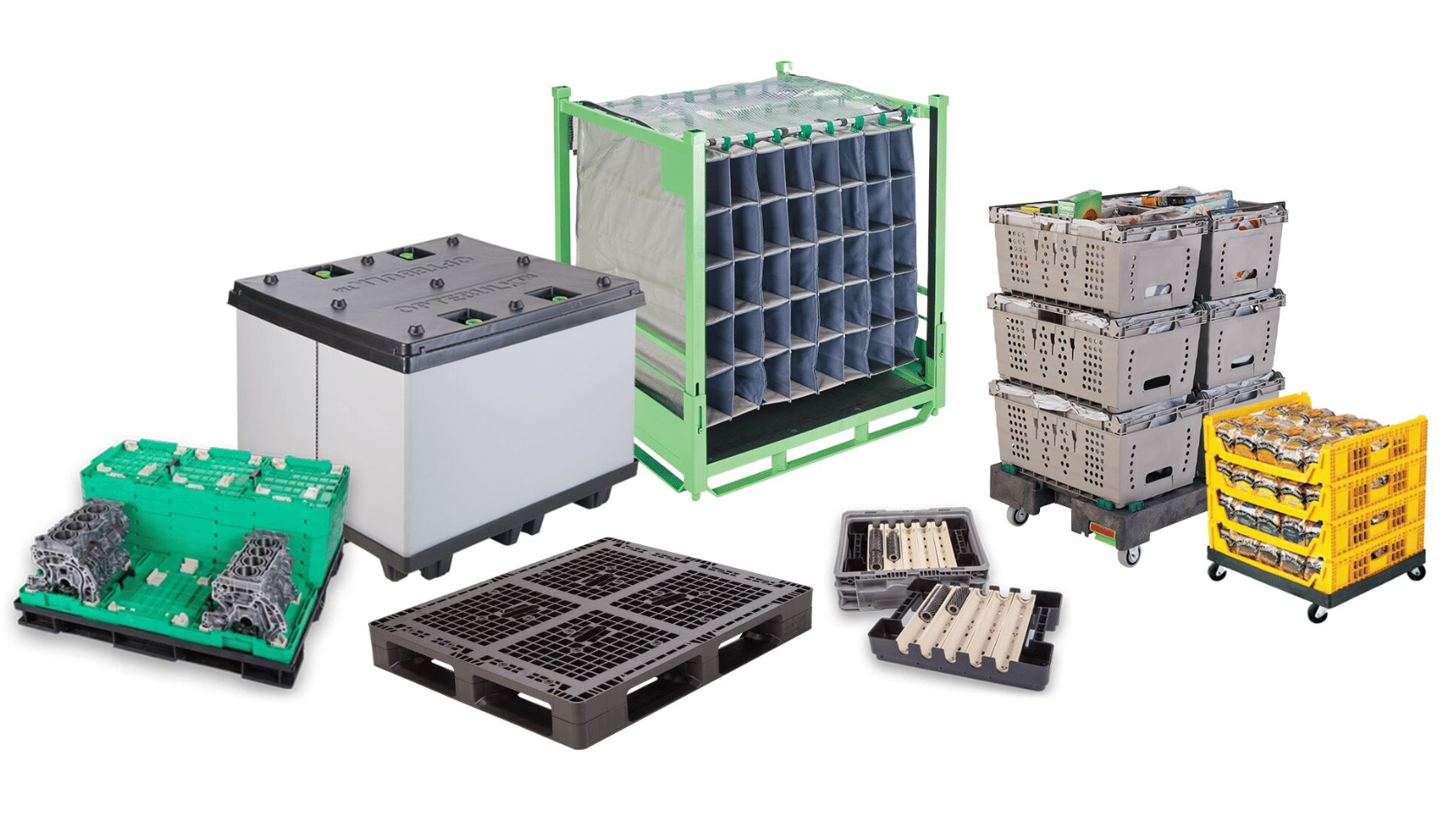

ORBIS is part of 175+ year old Menasha Corporation. Since 1996, ORBIS has led the way in providing reusable packaging solutions. Our reusable plastic containers, dunnage, pallets, and bulk containers are designed to meet PPWR compliance requirements from day one.

We support companies at every step of the PPWR implementation process:

Step 1: Legal Compliance – We analyze your supply chain to understand your current packaging portfolio and identify which packaging is affected by PPWR requirements. We work with Pacoon, a German-based sustainability consulting agency, to connect you with PPWR compliance experts who can help you understand your legal obligations.

Step 2: Solutions & Development – For those areas where gaps exist to be compliant with the PPWR, packaging options are identified and evaluated against the criteria a client deems essential. Ultimately, packaging is selected that ultimately meets the customer requirements and PPWR regulations. Some of the options are reusable, and some are designed to be recycled, but all must be PPWR compliant.

Step 3: Execution – The selected packaging options are tested in the customer’s supply chain. Additionally, an understanding of the infrastructure requirements, standard operating procedure changes with the new packaging, and reuse/recycle process is part of this step.

ORBIS is committed to sustainability and circular economy principles that align with PPWR’s objectives. We’re not just helping companies comply, we are helping them build more efficient, cost-effective, and environmentally responsible supply chains.

For companies that need hands-on guidance throughout the entire process, our PPWR support services provide personalized consultation and implementation support.

What's At Stake

The companies that are preparing now will gain a decade-long competitive advantage.

They’ll have established relationships with packaging suppliers before capacity constraints emerge. They’ll have optimized reverse logistics systems while competitors are still building databases. They’ll have trained teams executing SOPs while others are scrambling to understand linked enterprise classifications.

Those who wait could face market exclusion – not just fines. PPWR took 21 years to develop, from initial concepts in 1994 to enforcement in 2025.

Companies compliant by 2030 will solidify leadership positions in their markets during the 2030-2040 decade. They’ll have the infrastructure, the partnerships and the operational expertise that late movers will struggle to replicate under time pressure.

Get Started Today

The clock is running. August 2026 is approaching fast.

Here’s how to begin:

- Assign a team leader to own PPWR compliance in your organization

- Ask the critical question – If you have customers or suppliers shipping to the EU: “Are you aware of PPWR?” Many aren’t.

- Follow the three-step process – Don’t skip steps. Legal obligations first, then solutions, then execution.

This regulation is bigger than one company or industry. It’s about making the world better for future generations. As part of the solution, reusable packaging can deliver economic savings, environmental benefits, and human well-being. Not many solutions can achieve all three.

Download the Free PPWR Compliance Guide