Late summer typically marks the start of Back-to-School season, but fluid milk plants begin planning during the springtime in advance of their August busy season. Plant managers and those involved in procurement have a ton on their mind and that shouldn’t include being concerned about where their milk crates are coming from.

Beyond product availability, fluid milk plants are seeking a quick-turn, just-in-time delivery as holding excess inventory is not a viable option; when dairies call, they need product immediately. And given the tight margins, they seek affordable pricing that can help protect their bottom line. That means collaborating with suppliers who can offer dependability and affordability along with a range of product and service solutions.

At ORBIS Corporation, our commitment to customers extends throughout the year. Here’s how we help fluid milk plants begin their early Back-to-School preparations:

Ongoing commitments to product improvements

We regularly make investments in tooling and presses that enable us to manufacture milk crates at even more affordable prices. These continued investments help our customers improve their bottom lines.

Enabling plants to make immediate decisions

We recognize time is of the essence with our fluid milk customers and provide them with the necessary products, support, and service so they can make key decisions that will impact inventory today and ensure no time is wasted.

Provide a one-stop solution for their reusable needs

At ORBIS, we handle multiple reusable needs for our customers. We understand our customers from all industries are busy enough and want to make their lives easier.

Offer a full range of dairy packaging solutions

We recognize fluid milk plants need packaging solutions that accelerate distribution processes and reduce labor touch points.

ORBIS Dairy Cases are designed for the efficient distribution of fluid milk products from fluid milk plants to grocery stores, convenience stores, and discount stores.

- Two dairy industry standard footprints

- Exceptionally reinforced corners and bottoms.

- Maintain their shape and performance through stacking, pressure washing, and transportation

- Fully recyclable at end of life

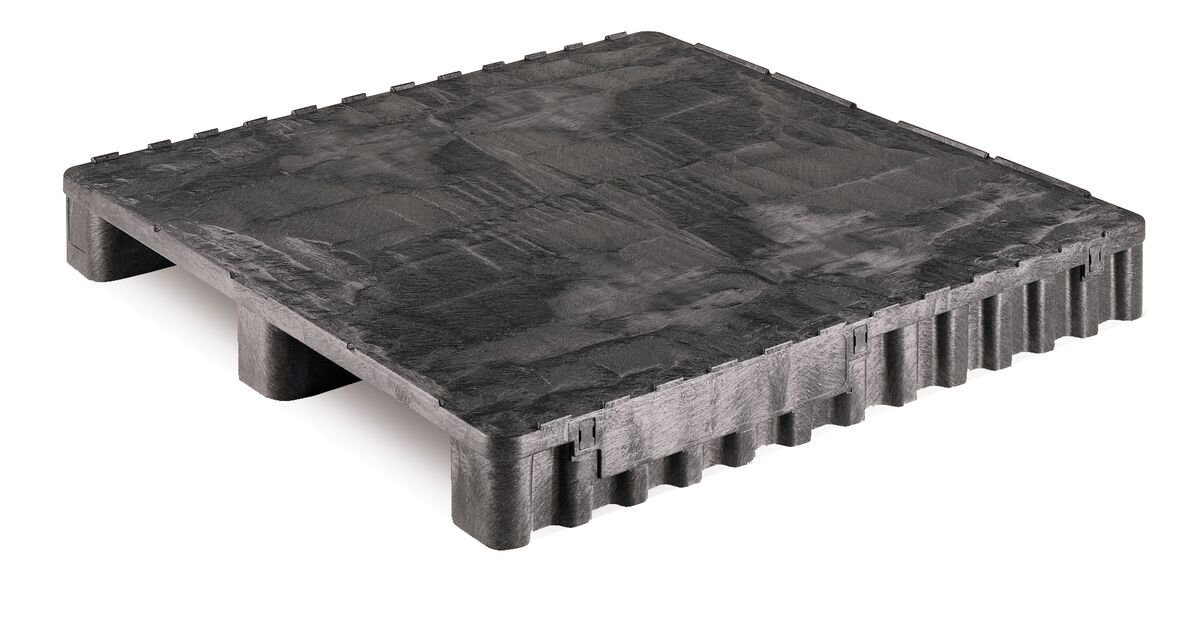

Specifically designed for and by the dairy industry, the ORBIS 40” x 40” Dairy Pallet is structurally foam-molded from heavy-duty HDPE, so it won’t crack, deflect, rot, or splinter like wood.

This pallet has a 3-stringer design that is compatible with most automated equipment and dairy systems. With a weight of 40 lbs., wet or dry, it surpasses OSHA’s guidelines.

The smooth, non-porous construction protects product (no nails, rust, or splinters) and does not absorb moisture or odor. Its all-plastic construction ensures dimensional consistency and repeatable performance during its entire service life.

- Available in FDA approved-compliant materials

- Available with standard or narrow stringer to fit your operations

- Long service life, with delivering lower per-trip cost than alternative pallets

- Consistent weight and size for accurate transportation costs

- Rackability up to 2,600 pounds

- Beveled lip to prevent load shifting